Time to read: 4 min.

You may have heard the term cross-docking, but do you know what it means? It is very common to come across unfamiliar terms used in our industry because some processes are not directly involved in our specific work area. However, these processes impact the final outcome and the satisfaction of customers by providing services when they want them and with the costs they expect.

In the last few years, the boom of e-commerce has caused an increase in the demand for knowledgeable logistics providers that can respond to the thousands of orders that are made daily. Cross-docking is a process proven to be one of the best solutions for responding with agility by speeding up delivery orders.

We have decided to take a moment to talk about this revolutionary process that has improved logistics effectiveness. This is cross-docking.

What Exactly is Cross-Docking?

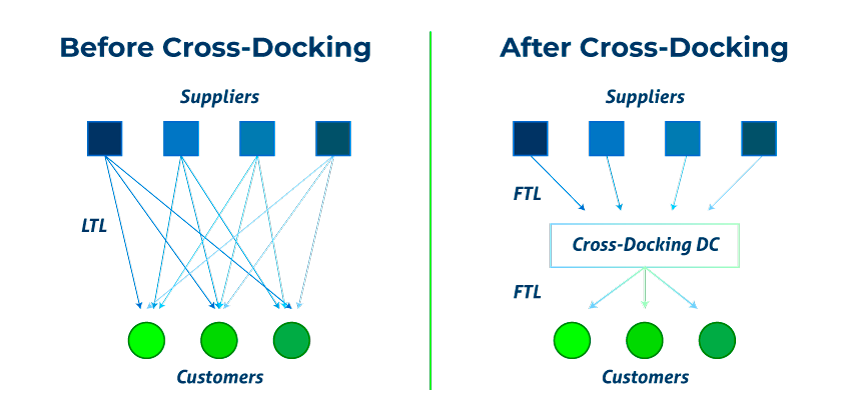

Cross-docking is considered a common strategy in the logistics industry. In a nutshell, it is the distribution of freight sent to a specially designed dock via semi-trailers, trucks, or rail. To carry out the distribution, shippers use technology to download the freight of inbound trucks and then they consolidate and sort the cargo into groups headed to the same place. Then, they upload the freight into outbound trucks following the schedule proposed. This seamless process causes storage time to be considerably reduced, as well as reduces the time in which the load remains on hold. Cross-docking is a process that keeps everything in constant motion.

To make this happen, digital logistics software and automated material handling tools are a must to keep shipments in motion and to create a constant flow. Why? Simple, automated handling tools create workflows quickly, increasing productivity and reducing human labor. Digital logistics software provides visibility to the entire process by delivering quick information, reports, and real-time status of shipped goods. By merging these two systems, you’ll have access to a synchronized environment that will help you to move your freight quickly and efficiently.

Who Invented This Practice?

The term sounds futuristic, but the truth is that cross-docking was invented in the 1930’s by the U.S. trucking industry. The technique is so efficient that it has been in permanent use in less-than-truckload operations ever since then.

What Does a Cross-Docking Site Look Like?

Facilities with 150 doors or less are usually designed in an “I” configuration, creating an elongated rectangle. This design was proposed by Bartholdi and Gue in 2004 as the most efficient design to successfully move freight directly across the dock from receiving door to shipping door. This configuration also improves the cost of traveling from door to door and reduces the time of cargo exposure in the handling process.

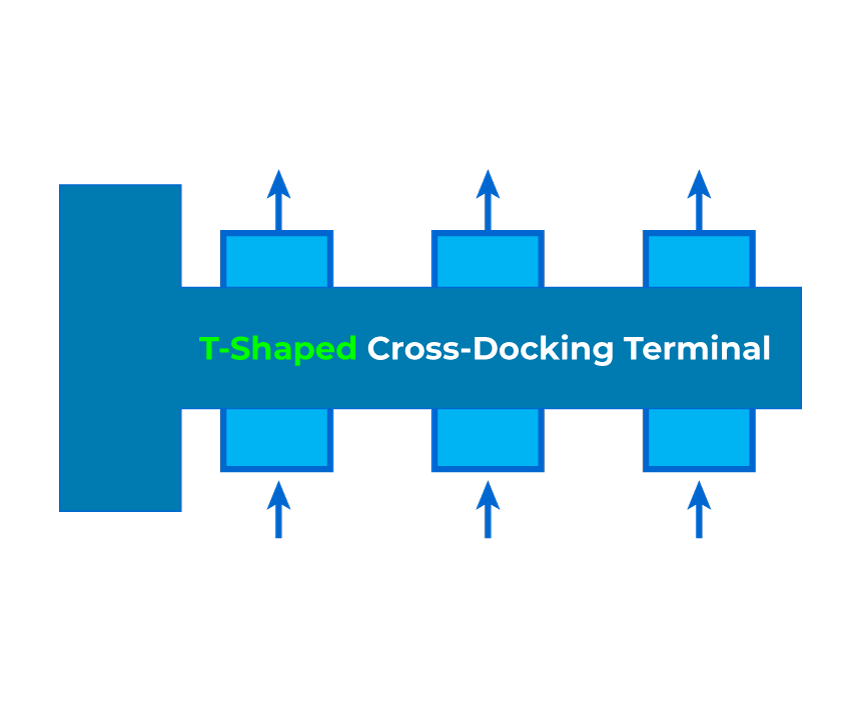

- For facilities with 150-200 doors, a “T” shaped terminal has been proven as most cost-effective.

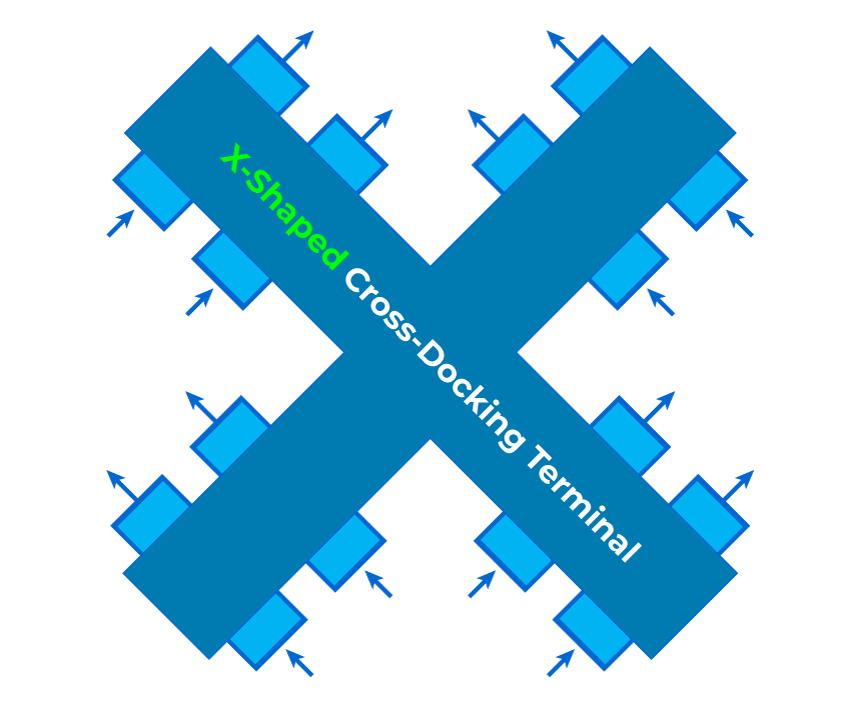

- For facilities with over 200 doors, an “X” shaped terminal is the most cost-effective design.

Process of Cross-Docking

The main idea is to download the products from inbound trucks, consolidate and sort the cargo in the middle of the warehouse shipping to the destination, and then immediately load the cargo on outbound trucks. Most freight leaves the warehouse in a couple of hours.

Advantages of Cross-Docking

There is a vast list of advantages that not only benefits the customer but also intermediaries. Here are just a few:

- Minimizes the need and cost of warehouse space

- Reduces inventory handling, helping your business move products faster

- Decreases freight handling, minimizing the risk of damaged goods

- Increases product quality

- Lower labor and transportation costs, due to decreased need to send trucks to different locations

- Reduces delivery time

- Increases customer service and customer experience

Disadvantages of Cross-Docking

- Product can be damaged if the packaging is not correct.

- Needs a computerized logistics system to operate

Conclusion

Without a doubt, cross-docking improves the efficiency and productivity of the supply chain process. This revolutionary technique allows you to reduce costs in warehousing, distribution, inventory and labor. It will also help you minimize the handling process which reduces the risks of damage. By leveraging this technique, you’ll find yourself immersed in a synchronized environment that will keep your operations in motion and will positively affect your customers’ experience.